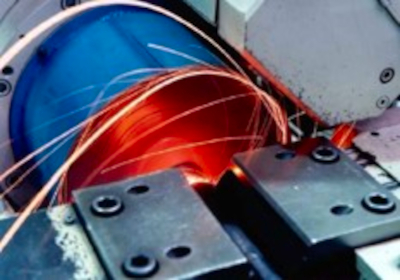

Our modern workshop is specially equipped for the production of small to medium-sized components, as well as shafts up to 2,000 mm in length. A total area of approx. 4,000 m² is available for mechanical production, including cutting.

The necessary technology is arranged according to the production flow so that transport distances are minimal.

Below you will find more information about our machinery and the contract manufacturing of turned parts, milled parts, balanced parts as well as friction welding. Other machines and systems are also available

- Band saw up to Ø 300mm

- CNC chuck part and shaft turning machine

- Conventional lathes up to a turning length of 3000 mm

- Conventional milling machines (vertical / horizontal)

- several welding workstations

- washing system

- colouring plant

We are also happy to take over the production of your components.

If you have any questions about contract manufacturing, please contact us directly

Gavin Machill

Phone: +49 3949 932 445

E-mail: machill@oddesse.de