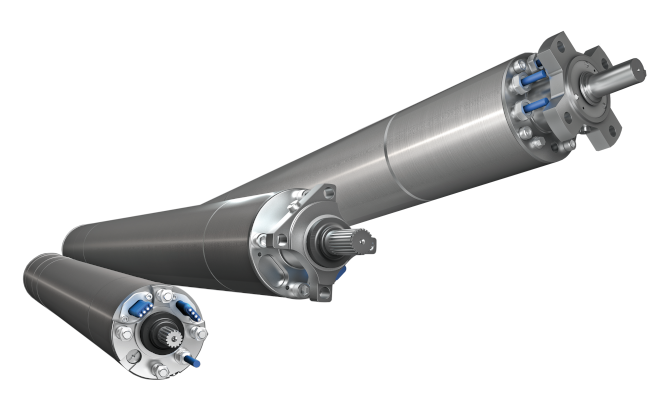

Types: po-mo / po-moh

The motors are designed as three-phase asynchronous motors with squirrel-cage rotors and waterproof windings. All motors are rewindable. For 100 years, the motors have been manufactured in oddesse and constantly developed further.

Operating data

| Delivery rate Delivery head Performance Voltage Type of current Frequency Degree of protection Ambient temperature |

… 1,200 m³/h … 600 m … 450 kW … 1,000 V 1~ and 3~ 50 and 60 Hz IP68 … 80 ° C |

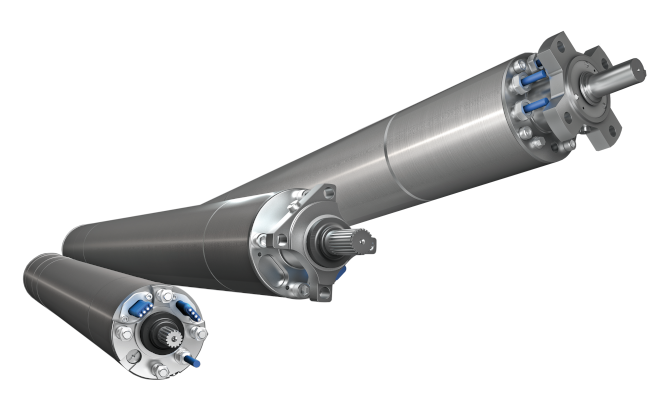

Types: po-mo / po-moh

The motors are designed as three-phase asynchronous motors with squirrel-cage rotors and waterproof windings. All motors are rewindable. For 100 years, the motors have been manufactured in oddesse and constantly developed further.

Operating data

| Delivery rate Delivery head Performance Voltage Type of current Frequency Degree of protection Ambient temperature |

… 1200 m³/h … 600 m … 450 kW … 1000 V 1~ and 3~ 50 and 60 Hz IP68 … 80 ° C |

Applications

- drive motors for well pumps for water supply

- drive of oddesse submersible pumps and pumps from many OEM partners

- pump drive for applications with high requirements such as in mining, for the use of geothermal energy as well as in offshore and marine technology

- drive motor for all submersible motor pumps with connection dimensions according to NEMA standard or international standards

Executions

- rewindable glandless motors

- motors according to NEMA standard or international standards

- motor filling made of biodegradable glycerin-water mixture

- mixture can be replaced by pure drinking water

- pressure nozzle with pipe thread or flange

- high-quality materials for use in industrial, process, geothermal and sea water

Advantages

- small outer diameter

- vertical and horizontal installation possible

- low plant and operating costs

- long maintenance-free run times

- adjustable by frequency converter

- low repair costs

- easy spare parts inventory thanks to the modular principle

- eco-friendly and recyclable

Materials

Component

|

Materials |

|||

G (GGG 40) |

C (AISI 304) |

X (AISI 316) |

Y (AISI 904L) |

|

| Shaft | Stainless steel / 1.4301 | Stainless steel / 1.4462 | ||

| Motor flange | GGG40 / 0.7040 | Stainless steel / 1.4301 | Stainless steel / 1.4571 | Stainless steel / 1.4539 |

| Motor casing | Stainless steel / 1.4306 | Stainless steel / 1.4571 | Stainless steel / 1.4539 | |

| Radial bearing | Steel / carbon | |||

| Thrust bearing | Steel / carbon | |||

| Fasteners | Stainless steel A2 / 1.4301 / 1.4303 | Stainless steel A4 / 1.4401 | Stainless steel / 1.4539 | |

| Mechanical seal | Coal / Ceramics | SiC / SiC | ||

Applications

- drive motors for well pumps for water supply

- drive of oddesse submersible pumps and pumps from many OEM partners

- pump drive for applications with high requirements such as in mining, for the use of geothermal energy as well as in offshore and marine technology

- drive motor for all submersible motor pumps with connection dimensions according to NEMA standard or international standards

Executions

- rewindable glandless motors

- motors according to NEMA standard or international standards

- motor filling made of biodegradable glycerin-water mixture

- mixture can be replaced by pure drinking water

- pressure nozzle with pipe thread or flange

- high-quality materials for use in industrial, process, geothermal and sea water

Advantages

- small outer diameter

- vertical and horizontal installation possible

- low plant and operating costs

- long maintenance-free run times

- adjustable by frequency converter

- low repair costs

- easy spare parts inventory thanks to the modular principle

- eco-friendly and recyclable

Special motors for high thermal loads

Special motors are supplied to our customers for water temperatures of up to 80 °C, with heavy clogging and little flow around them. By using high-quality, temperature-resistant winding wire, the motor filling circulates more effectively and heat dissipation through the internal cooling circuit is improved.

Use in the tidal power plant in the China Sea

The special motors with seawater-resistant materials are used to drive booster pumps. They can be rewound and are equipped with temperature-resistant winding wire. High quality underwater cable couplers are used to disconnect and couple the motors while submerged.