A modern test facility is available in our production side in Oschersleben for the development and testing of oddesse submersible pumps and motors. Here, several submersible motors and submersible motor pumps can be tested simultaneously with computer support. The maximum drive power is 400 kW at 50 Hz, 450 kW at 60 Hz and 300 kW at 100 Hz.

The test basin with well imitations embedded in the hall floor is 6 m deep, holds approx. 300,000 l of water and allows the installation of submersible pumps up to an overall length of 5 m. From the central evaluation and operating station, graduated flow measurement distances of 3 to 2500 m³/h and delivery heads of up to 400 mWS can be simulated.

In addition to testing oddesse products, we also offer our customers the testing of pumps and motors from other manufacturers. The special thing about this is that we can adapt the pumps to defined delivery parameters at the customer’s request and also provide detailed evidence of these with a test report.

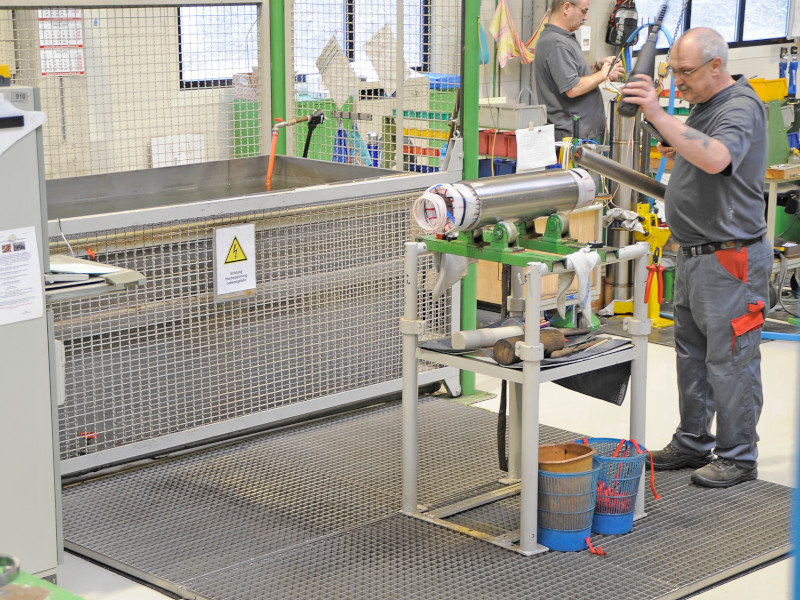

In addition, oddesse has a separate stator test bench and a test field for the electrical tests of the motors, as well as a test bench for the electrical tests and a wet-running test tank for the drainage pumps.

Applied standards

- ISO 9906 Centrifugal pumps – hydraulic proof test 1, 2 and 3

- DIN EN 60034-2-12015 for motor testing

Available Measurements

- Delivery characteristics of submersible pumps with all the necessary performance data

- Performance curves of submersible motors

- Endurance tests of submersible motors and submersible pumps

- Determining the self-heating of submersible motors

- Acquisition of torque and speed characteristics of submersible motors

We are at your disposal at any time for further information about our test field

Test field for submersible pumps

The test basin with well imitations embedded in the hall floor is 6 m deep, holds approx. 300,000 l of water and allows the installation of submersible pumps up to an overall length of 5 m. From the central evaluation and operating station, graduated flow measurement distances of 3 to 2500 m³/h and delivery heads of up to 400 mWS can be simulated.

Tests of drainage pumps

The production line for the drainage pumps includes a test bench for all electrical measurements as well as a wet-running test tank. In addition to measuring the insulation value and the high voltage, a functional run of the pumps is also carried out.

Tests of submersible motors

The wound stators first undergo a high-voltage test and insulation measurement. After completion of the motors, they are subjected to all prescribed electrical tests and a functional run is carried out.