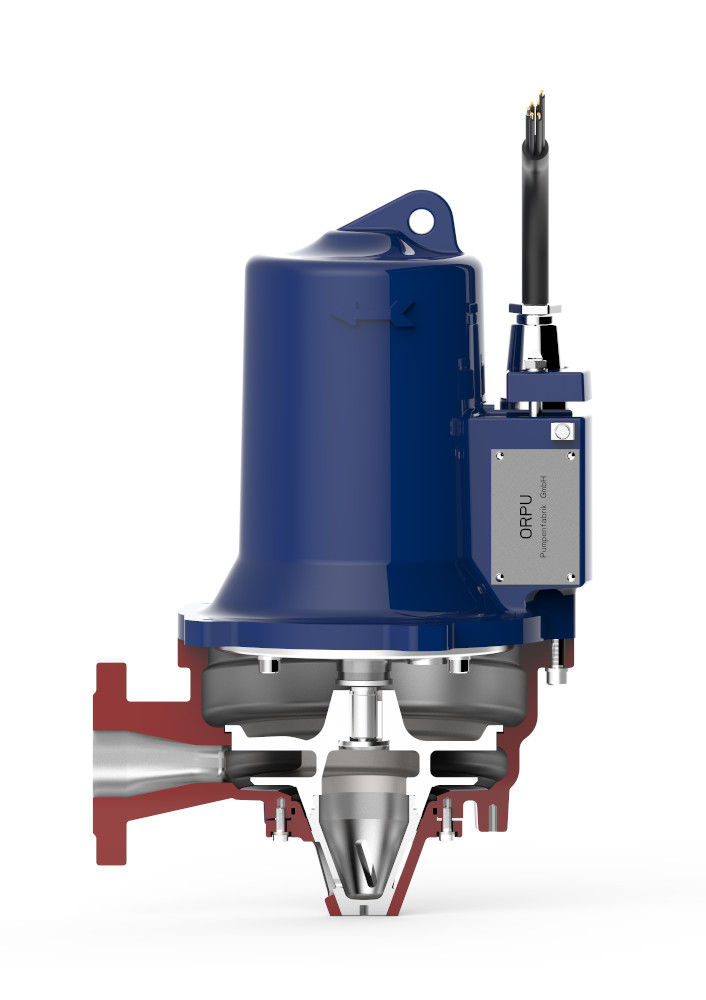

Types: ORCUT / po-w

The ORCUT TMS, TES, ES and KM grinder pumps are manufactured by ORPU Pumpenfabrik GmbH, an oddesse subsidiary in Oranienburg. These pumps are characterised by a tried-and-tested, effective multiple-grinder system and are operated with motors of efficiency class up to IE3.

Operating data

| Delivery rate Delivery head Performance Voltage Type of current Frequency Degree of protection Ambient temperature |

… 520 m³/h … 60 m … 26 kW … 690 V 1~ and 3~ 50 Hz IP68 … 40 °C |

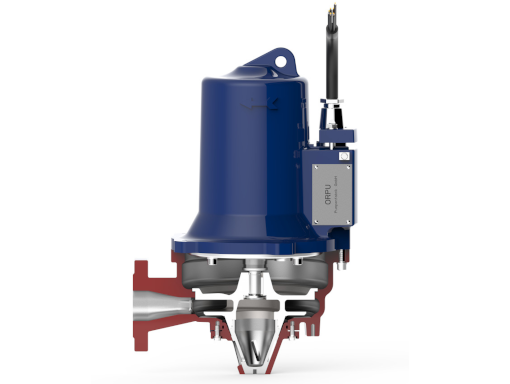

Types: ORCUT / po-w

The ORCUT TMS, TES, ES and KM grinder pumps are manufactured by ORPU Pumpenfabrik GmbH, an oddesse subsidiary in Oranienburg. These pumps are characterised by a tried-and-tested, effective multiple-grinder system and are operated with motors of efficiency class up to IE3.

Operating data

| Delivery rate Delivery head Performance Voltage Type of current Frequency Degree of protection Ambient temperature |

… 520 m³/h … 60 m … 26 kW … 690 V 1~ and 3~ 50 Hz IP68 … 40 °C |

Applications

- delivery of raw and sewage water with solid components at purification plants and pump stations

- local drainage, dewatering and industrial water removal

- delivery and breakup of contaminated dirty and sewage water, primarily in pressure drainage applications

- homogenisation of the delivered medium

- especially suitable for membrane purification plants on land or at sea

Executions

- single-stage centrifugal pumps, suitable for wet, dry and mobile set-up

- single-channel impeller or vortex impeller

- available with cutting system

- single-phase or three-phase motor, protection level IP 68

- explosion-protection possible

- motor sealing via high-quality mechanical seals

Advantages

- available in standard and explosion-proof versions

- blockage-free operation, either through the use of a patented cutting system or

by ensuring the passage of large particles - stationary or mobile use

- wet or dry installation

- DIN flange DN 32 to DN 150 for PN 6 and PN 10 can be used

- spiral hose connection possible

- comprehensive accessories

- highly efficient

- cost-efficient installation

- high operational reliability

- long service life

- effluent containing fibres and solids, faeces

- delivered medium temperatures up to 40 °C

- comprehensive service network

Materials

| Component | Execution | |

| po-ws/we | ORCUT TES | |

| Casing | GG | GG 20 |

| Cutting system | NITRO hardened | Stainless steel / 1.4528 |

| Impeller | GG | GG 20 |

| Shaft | Stainless steel | Stainless steel / 1.4021 |

| Mechanical seal | SiC | SiC/SiC |

Applications

- delivery of raw and sewage water with solid components at purification plants and pump stations

- local drainage, dewatering and industrial water removal

- delivery and breakup of contaminated dirty and sewage water, primarily in pressure drainage applications

- homogenisation of the delivered medium

- especially suitable for membrane purification plants on land or at sea

Executions

- single-stage centrifugal pumps, suitable for wet, dry and mobile set-up

- single-channel impeller or vortex impeller

- available with cutting system

- single-phase or three-phase motor, protection level IP 68

- explosion-protection possible

- motor sealing via high-quality mechanical seals

Advantages

- available in standard and explosion-proof versions

- blockage-free operation, either through the use of a patented cutting system or

by ensuring the passage of large particles - stationary or mobile use

- wet or dry installation

- DIN flange DN 32 to DN 150 for PN 6 and PN 10 can be used

- spiral hose connection possible

- comprehensive accessories

- highly efficient

- cost-efficient installation

- high operational reliability

- long service life

- effluent containing fibres and solids, faeces

- delivered medium temperatures up to 40 °C

- comprehensive service network

Grinder pumps for sewage transport

In the Czech Republic, ORPU cutter pumps are used in pressure drainage systems for sewage transport. The effectively and reliably working cutting wheel system guarantees blockage-free operation of the pump, even with atypical solids. This leads to considerable cost advantages in rural areas.

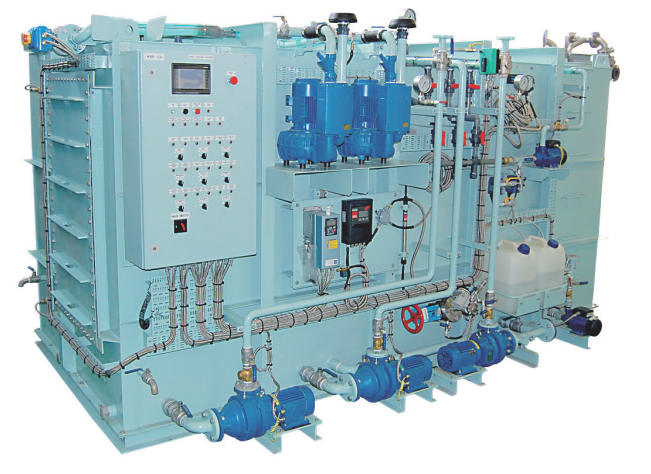

Waste water treatment on ships

The dry-installed macerator pumps with a 3-stage cutting system are used in membrane treatment plants to treat the waste water on Finnish ships. The pumps are ideally suited to meet the wastewater treatment requirements of ships and ferries and thus make their contribution to the protection of our oceans.