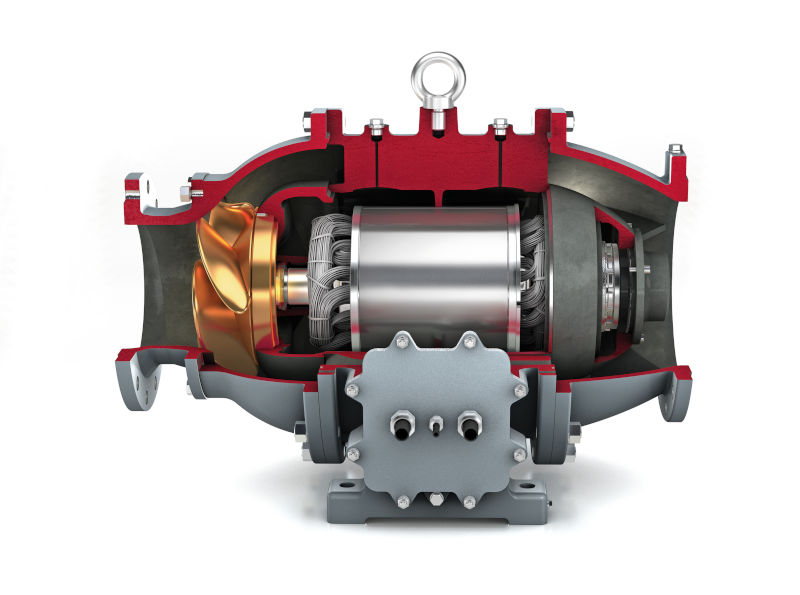

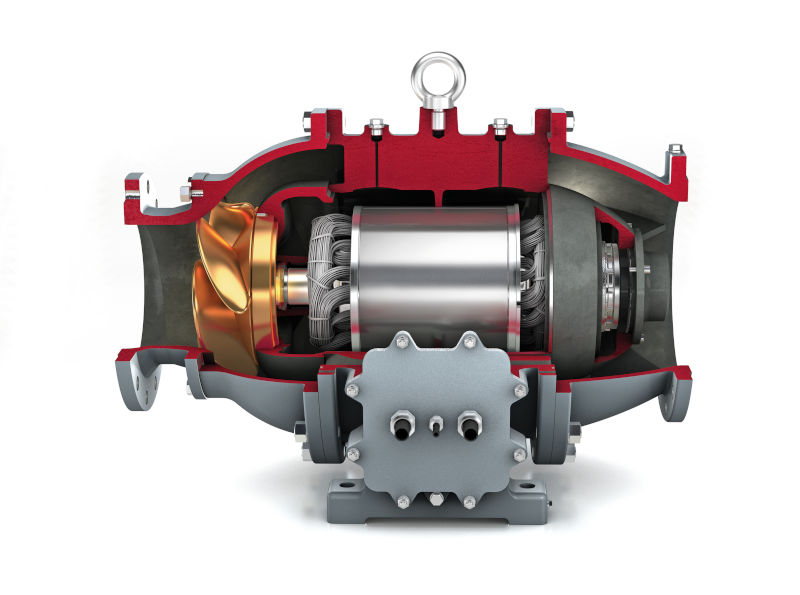

Type: po-upl / po-upl-s

Single-stage centrifugal pumps with open half-axial impeller with asynchronous three-phase or permanent magnet synchronous motor for pumping clean and slightly contaminated water.

Operating data

| Delivery rate Delivery head Performance Voltage Type of current Frequency Degree of protection Ambient temperature |

… 1.150 m³/h … 35 m … 55 kW … 500V 3~ … 60 Hz IP68 … 50 ° C |

Type: po-upl / po-upl-s

Single-stage centrifugal pumps with open semi-axial impeller with three-phase or permanent magnet synchronous motor for pumping clean and slightly dirty water.

Operating data

| Delivery rate Delivery head Performance Voltage Type of current Frequency Degree of protection Ambient temperature |

… 1.150 m³/h … 35 m … 55 kW … 500V 3~ … 60 Hz IP68 … 50 ° C |

Applications

- Irrigation and drainage of agricultural land

- Water level regulation (pump station and polder pumps)

- Circulation of water in sewage treatment plants

- Oxygen enrichment of fish farm rearing waters

- Trimming ships, ferries and tankers

- Draining or flooding of floating docks

- Emptying or flooding of tanks

- clean or slightly dirty water with a solids content of up to 50 mg/l

- fresh water, sea water and brackish water

- Pumped medium temperatures up to 50 °C

Executions

- single-stage centrifugal pumps with open semi-axial impeller

- submersible, rewindable and water-filled motors with protection class IP 68

- also available as a highly efficient permanent magnet synchronous submersible motor

- motor cooling through pumped medium that flows around it

- water-lubricated, radial and axial slide bearings

- motor encapsulation by mechanical seal

- optimal motor filling guaranteed by a volume-compensation system

- rubber-sheathed electrical cable, watertight connected

- continuous operation, switching operation or frequency control

- Operation of the po-upl-s only possible with frequency converter

- tandem operation

- high-quality materials for application in service, industrial and sea water

Advantages

- installation in vertical or horizontal position

- operation as in-line pump or submerged

- tandem and back-to-back arrangement possible

- excellent cooling thanks to water-filled motor and pumped medium flowing around the motor

- rewindable motor encapsulated via shaft seal, no mechanical feed-through to the outside

- adjustable by frequency converter

- long maintenance-free run times

- low repair costs

- low plant and operating costs

- environmentally friendly – fully recyclable

- comprehensive service network

Materials

| Component | Materials |

| Impeller | CuSn10/ 2.1050 |

| Casing |

Grey cast iron GG25 / 0.6025 / CuSn10 / 2.1050 CERAM coating possible – offers protection against corrosion and minimises life cycle costs. |

| Shaft | Stainless steel |

| Radial bearing | Bronze / stainless steel |

| Mechanical seal | SiC / SiC |

Applications

- Irrigation and drainage of agricultural land

- Water level regulation (pump station and polder pumps)

- Circulation of water in sewage treatment plants

- Oxygen enrichment of fish farm rearing waters

- Trimming ships, ferries and tankers

- Draining or flooding of floating docks

- Emptying or flooding of tanks

- clean or slightly dirty water with a solids content of up to 50 mg/l

- fresh water, sea water and brackish water

- Pumped medium temperatures up to 50 °C

Executions

- single-stage centrifugal pumps with open semi-axial impeller

- submersible, rewindable and water-filled motors with protection class IP 68

- also available as a highly efficient permanent magnet synchronous submersible motor

- motor cooling through pumped medium that flows around it

- water-lubricated, radial and axial slide bearings

- motor encapsulation by mechanical seal

- optimal motor filling guaranteed by a volume-compensation system

- rubber-sheathed electrical cable, watertight connected

- continuous operation, switching operation or frequency control

- Operation of the po-upl-s only possible with frequency converter

- tandem operation

- high-quality materials for application in service, industrial and sea water

Advantages

- installation in vertical or horizontal position

- operation as in-line pump or submerged

- tandem and back-to-back arrangement possible

- excellent cooling thanks to water-filled motor and pumped medium flowing around the motor

- rewindable motor encapsulated via shaft seal, no mechanical feed-through to the outside

- adjustable by frequency converter

- long maintenance-free run times

- low repair costs

- low plant and operating costs

- environmentally friendly – fully recyclable

- comprehensive service network

Oxygen enrichment in oyster farming

The po-upl propeller pumps are used as circulation pumps for oxygen enrichment in a French oyster farm. The pumps can be used horizontally or vertically and are operated with frequency converters.

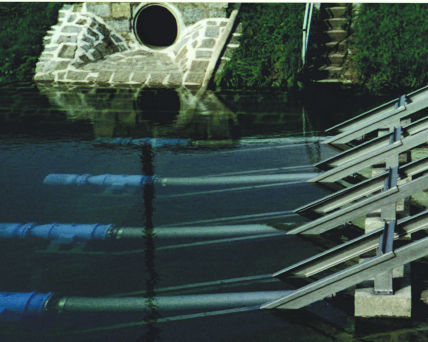

Drainage in flood protection

In Germany, the propeller pumps are used, among other things, as drainage pumps for flood protection. The pumps with inlet basket are mounted on slide rails and have an automatic clutch system.

Use in recirculating aquaculture systems

In Norway and Canada, the po-upl propeller pumps are used in recirculating aquaculture systems (RAS) for aeration and oxygenation of aquacultures.